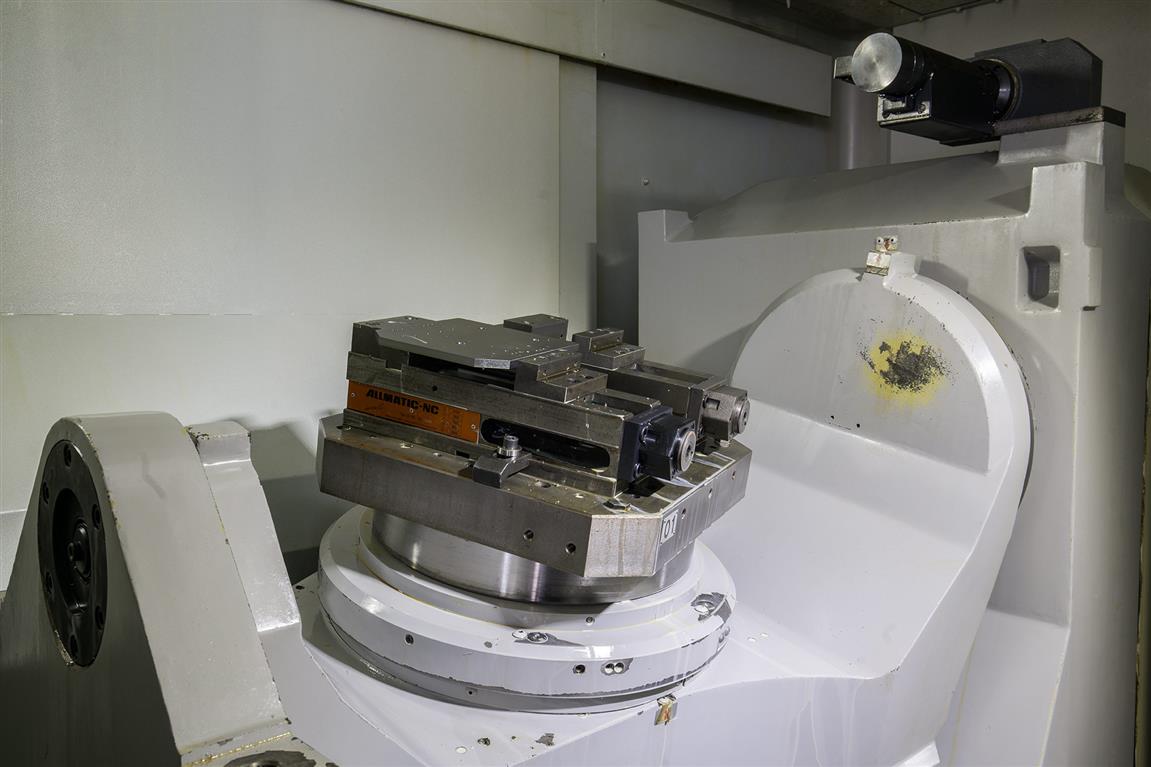

MORI SEIKI

MORI SEIKI NMH 5000 DCG | Vintage: 2011

Machining Center - Universal

1070-400065

Control: CNC, MSX 711 Mapps IV

Made in JapanFast state of the art 5-axis machining center with twin 500mm pallet changer, full A- and B-axis, high pressure coolant through spindle Frascara 50 bar, chip conveyor, tool length measurement and tool breakage detector. 120 tool magazine HSK-A 63, Renishaw probe. Machine is in excellent condition with little run hours.

Delivery

Condition: GebrauchtDelivery time: immediately

Freight basis: EXW (Incoterms 2010) free loaded on truck

Storage location:

Details MORI SEIKI NMH 5000 DCG

x-travel 730 mmy-travel 850 mm

z-travel 1100 mm

control MSX 711 MAPPS IV

Spindle power 22 / 18,5 kW

Spindle RPM 12000 1/min

Tool magazine 120 HSK-A 63

max. tool diameter 70 mm

Max. Tool dia with free space next in magazine 140 mm

max. tool length 480 mm

max. tool weight 12 kg

rapid travel x/y/z 50.000 mm/min

A-axis (5th axis) pivoting table +30° -120° °

B-axis fully integrated 360.000 x 0,001°

Rapid Rpm B-axis (rotary table) 50 1/min

Rapid feed A-axis (tilt axis) 20 1/min

Pallet changer 2x 500 x 500 mm

max. workpiece weight 500 kg

workpiece - installed height 700 mm

max. workpiece diameter on pallets 700 mm

total power requirement 63 kVA

weight of the machine ca. 21 t

dimensions of the machine ca. 6,0 x 6,1 x 3,3 m

Number of coordinate systems 300

Milling of pockets and islands

MAPPS tool management system GB

chip conveyor

spindle oil cooler

Load monitor

Coolant Gun

Memory 1 MB

Probe for tool breakage and length measuring

Tool life management

Registered Programs 1000

Renishaw probe (spindle)

3 dimensional Tool offset

Signal lamp 3 colors

Quick fixed cycles

Coolant through spindle 50 bar with filter Frascara

Pictures of the MORI SEIKI NMH 5000 DCG